Home » Ranch Fences » Cattle Fences

Barbed wire has been the standard of cattle fences for years, now, there is a new cattle fence solution for ranchers and property owners: High tensile fixed knot steel mesh fencing, designed to provide greater security and long service life. This means lower overall long-term expenses in terms of replacement costs and maintenance.

Another benefit of high tensile mesh over the barbed wire is that feral hogs cannot make it through or destroy this style of fence, preserving your fields for hay and grazing without the constant damage that hogs inflict.

With a wide range of height and mesh pattern options, Tejas Ranch & Game Fence can install the livestock fence that best suits your needs. It is assured of providing you with a cattle fence with many years of service life.

We offer additional features, such as predator control barriers and water gap installation, allowing you to customize your cattle fence to suit virtually any requirement.

For the ultimate steel mesh protection in severe environments such as coastal areas, we offer a zinc-aluminum coating that is highly resistant to corrosion.. This Class 40 Zinc-Aluminum coating provides the highest degree of protection for high-tensile steel mesh.

Time to protect your valuable cattle. Request a cattle fence estimate from a professional cattle fence contractor to get started. [REQUEST ESTIMATE]

The Class 3 galvanized coating on our fence materials is proven to last three times longer than Class 1.

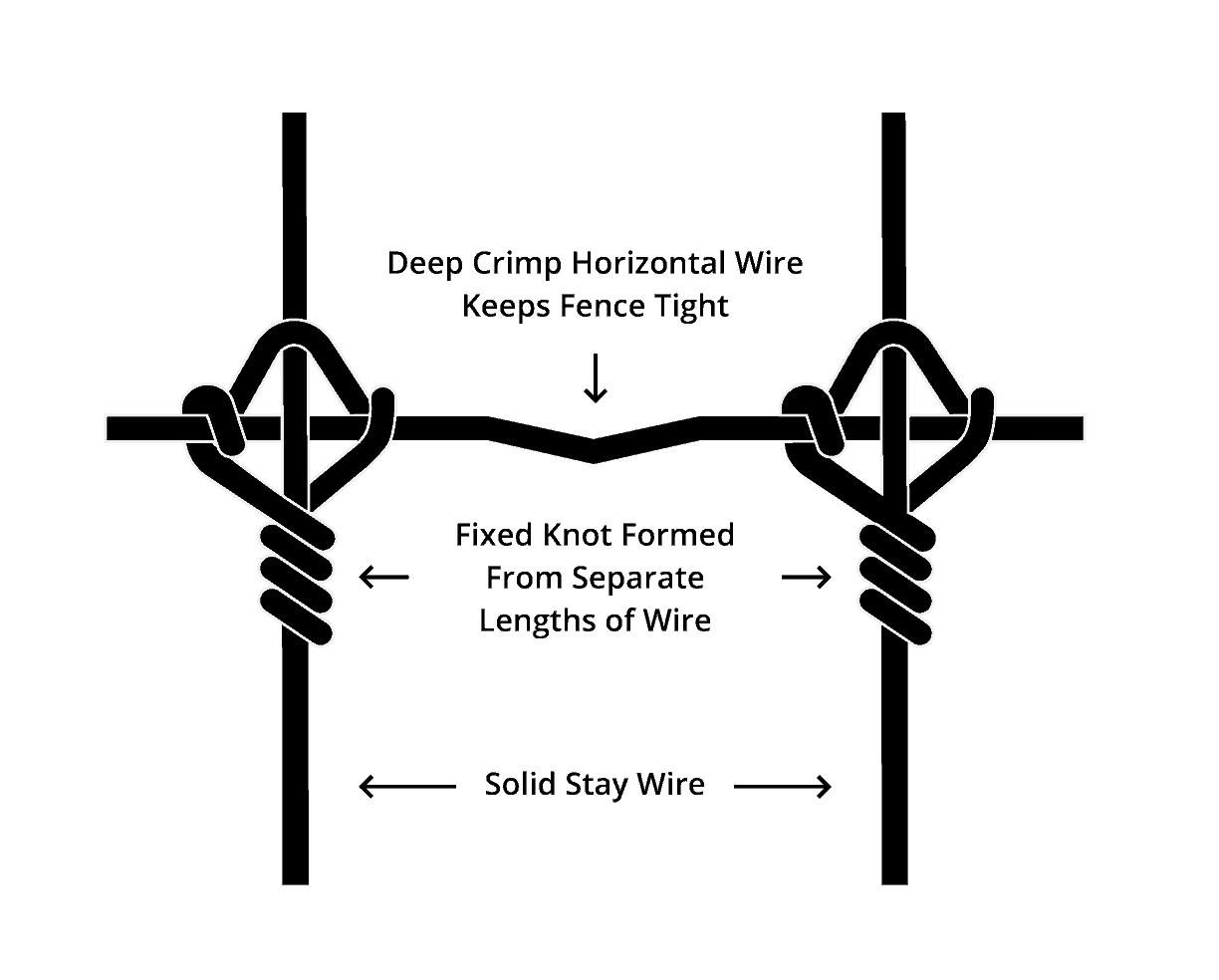

The fixed knot design of our fence mesh provides greater strength and performance than hinge-joint mesh.

The varying mesh spacings, with smaller “holes” toward the bottom of the fence, helps ensure greater security from unwanted animals while maintaining an affordable fence solution.

The steel mesh is designed to withstand stresses without losing shape or strength. The crimps in the horizontal wires absorb pressure – both during installation and from animals.

Cattle fencing forms the backbone of successful ranch operations across the country. The right fence keeps your herd safe, protects your investment, and saves countless hours of maintenance over the years. Modern ranchers have moved beyond traditional barbed wire to more effective solutions that deliver superior performance and long-term value.

Proper cattle fencing serves multiple functions on working ranches, including protecting livestock from predators, preventing cattle from wandering into dangerous areas, and helping manage grazing patterns for optimal pasture health. Quality fencing also protects your investment by reducing livestock losses and eliminating the constant headaches of escaped animals. The choice of cattle fencing material can impact your operation for decades, making it essential to consider total ownership expenses, including maintenance, repairs, and replacement costs over the fence’s lifetime.

High-tensile fixed-knot steel mesh represents the most advanced cattle fencing technology available today. This system outperforms traditional options in every category that matters to working ranchers, thanks to its superior strength, durability, and animal safety. The fixed knot design locks horizontal and vertical wires together permanently using a continuous wrapping technique that prevents wire movement and maintains original tension throughout the fence’s service life.

The steel mesh withstands impact from cattle without losing structural integrity or developing permanent deformation. Varying mesh patterns provide smaller openings toward the bottom while larger spacing at the top reduces material costs. Class 3 galvanized coating lasts three times longer than basic galvanization, while zinc-aluminum coating provides ultimate protection in coastal areas. High-tensile systems allow 15- to 20-foot post spacing, reducing installation costs compared to traditional alternatives.

Barbed wire cattle fence has served as the standard cattle fencing for over 150 years due to its low initial costs and simple installation. However, cattle suffer hide damage from contact with barbs, which reduces animal value and creates potential health problems. The material requires frequent maintenance, as traditional steel tends to stretch under tension and weather stress.

Many ranchers now use a single strand of barbed wire above high-tensile mesh systems. This configuration provides predator deterrence while minimizing safety risks by positioning the barbed strand above normal cattle contact height.

Traditional woven wire uses hinged joint connections that allow movement at wire intersections. This flexibility enables the fence to conform to terrain variations and works well for mixed livestock operations that contain multiple species. However, hinged joints weaken over time as repeated stress causes connections to loosen and create permanent deformation.

Field fence typically costs less initially than fixed knot systems but requires more frequent replacement after 15 to 20 years. Fixed knot systems often provide better long-term value with 30 to 40 years of service and minimal maintenance requirements.

Electric fencing creates psychological barriers through mild shock conditioning that trains cattle to respect boundaries. The technology works well for temporary installations and rotational grazing systems, requiring a minimum of 700 volts for reliable cattle control. Electric systems complement permanent fencing but require consistent power sources and regular vegetation management to prevent short circuits.

Standard cattle fences should measure 49 inches tall for most applications, with bulls and larger breeds requiring heights of 54 to 60 inches. Post spacing varies by fence type, with high-tensile fixed-knot systems allowing 15 to 20-foot spacing between posts, while traditional barbed wire requires posts every 12 to 16 feet. Corner posts bear the most significant stress and should measure 8 inches in diameter, extending into the ground equal to or greater than the height of the top wire.

Tejas Ranch & Game Fence recommends cattle fence material with nine horizontal wires standing 49 inches tall. Vertical spacing options include 12-inch spacing for boundary and long-distance pasture fences, 6-inch spacing for internal or corral use requiring greater strength, and 3-inch spacing for maximum strength in high-pressure areas. The graduated mesh design with smaller holes toward the bottom helps maintain security from unwanted animals while keeping costs affordable.

Mistake |

Correct Approach |

| Using undersized corner posts or setting them too shallow | Install 8-inch diameter corner posts buried at least as deep as the fence is tall. Utilize proper bracing systems, such as floating diagonal braces, to distribute tension loads effectively. |

| Incorrect post spacing for fence type | Follow manufacturer recommendations. High-tensile systems allow 15-20 foot spacing, while barbed wire requires posts every 12-16 feet. Use stays between widely spaced posts if needed. |

| Wrong energizer size for electric systems | Use 1 joule of output per mile of fence. A 6-mile perimeter requires a minimum of 6 joules of energizer. Undersized units fail to maintain proper voltage levels. |

| Ground rods placed too close together | Space ground rods throughout the fence line, not clustered near the energizer. Use 3 feet of ground rod per joule of energizer output, spaced at least 6 feet apart. |

| Using steel posts with an electric fence | Select plastic or composite posts for use in electric systems. Steel posts cause short circuits even with insulators, which eventually crack or pop off under stress. |

| Poor planning and property line mistakes | Survey property boundaries before installation. Check for underground utilities, plan gate locations during the design phase, and consider future expansion needs to ensure a seamless operation. |

Our team brings almost three decades of experience in designing and installing high-performance cattle fencing systems. We understand that every ranch has its challenges, from terrain variations to specific livestock requirements, and we work closely with property owners to develop customized solutions that deliver long-term value. Our expertise in high-tensile fixed knot systems means you get a fence that performs reliably for decades while requiring minimal maintenance.

We stand behind our work with superior materials and proven installation techniques that have served ranchers across diverse environments and applications. As an experienced cattle fence contractor we handle everything from standard pasture fencing to complex water gap installations and predator control systems, with our skilled team having the knowledge and equipment to manage projects of any size or complexity. When you choose Tejas Ranch & Game Fence, you partner with professionals who are as invested in your success as you are.

Tejas Ranch & Game Fence

10010 Highway 175 West

Athens, TX 75751