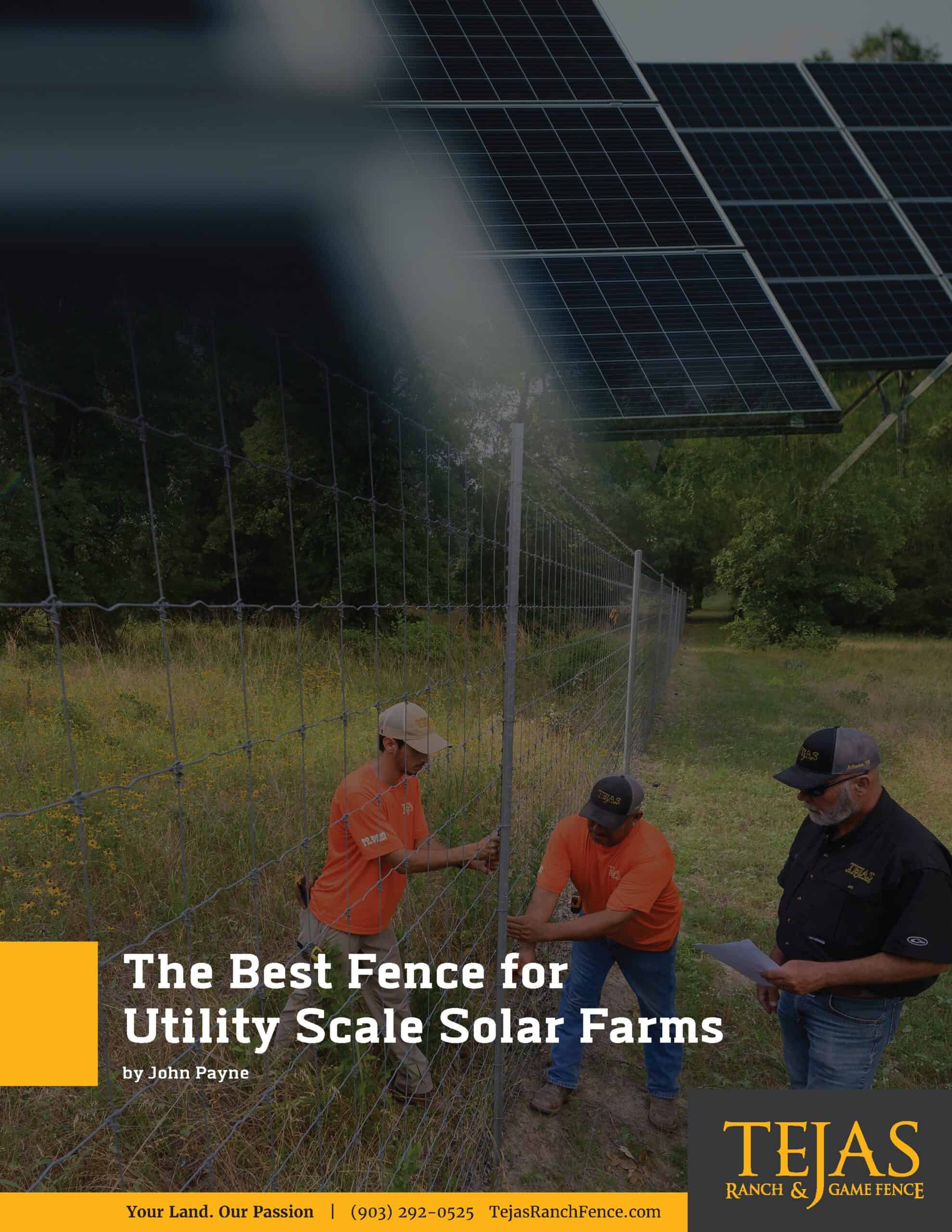

Protect your investment with the best solar farm fence.

Whether your goal is to:

- Prevent damage to solar panel units, substations, or other necessary structures

- Secure the perimeter from tampering or theft

- Exclude wildlife that can damage these panels

- Reduce accidents and repair costs

Our best solar farm fence solutions set the standard for value, durability, and reliability.

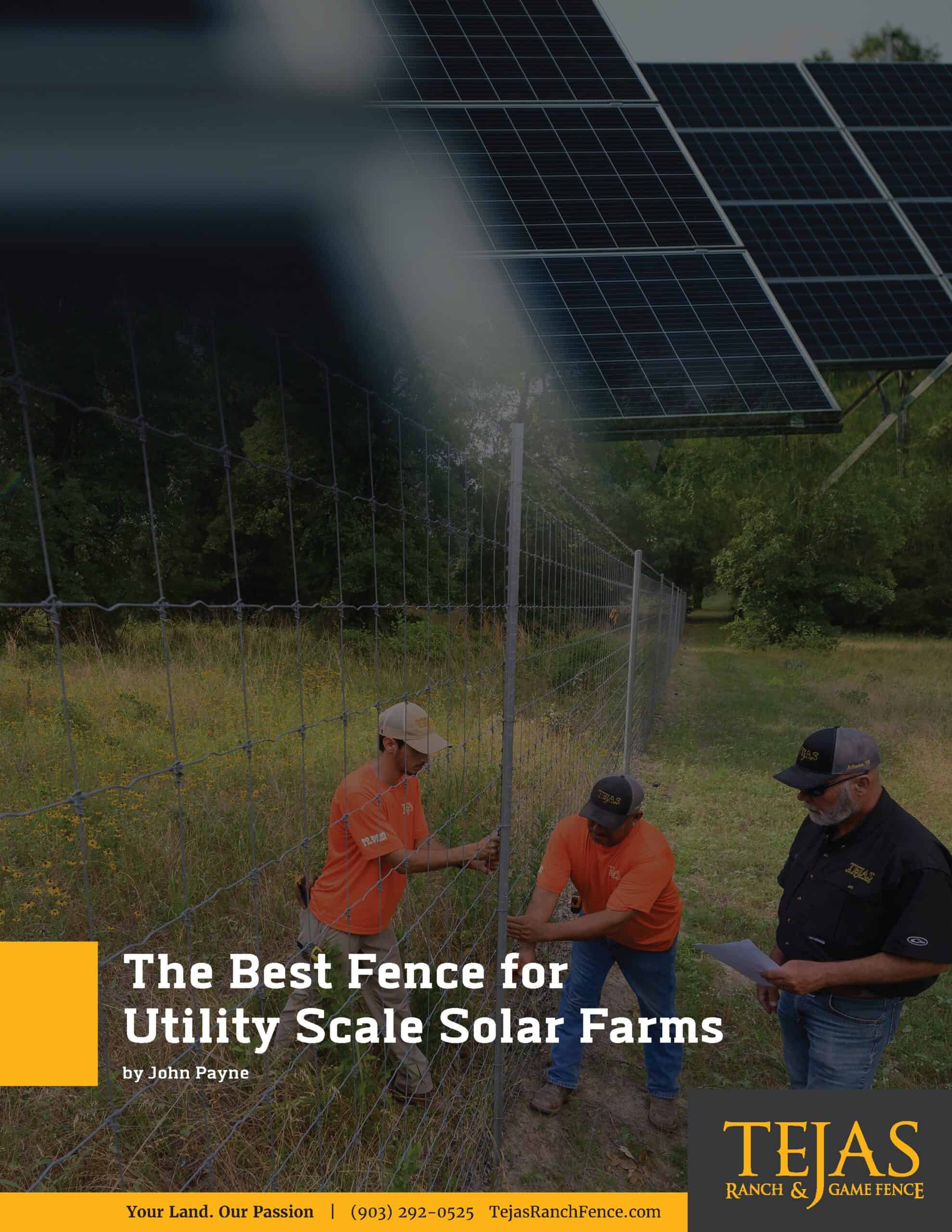

HIGH-TENSILE, FIXED-KNOT FENCE

While chain-link fences are commonly used around utility-scale solar arrays, they are often less aesthetic and less effective—particularly in rural settings—compared to high-tensile, fixed-knot fencing.

This fencing solution offers strength and durability, resisting tampering, livestock impacts, and wildlife pressure. High-tensile, fixed-knot fencing is designed to withstand human and animal forces and performs superiorly in staying intact under extreme stress.

Here, we delve into the materials, performance, benefits, costs, specifications, and customization options for high-tensile, fixed-knot fencing.

HIGH-TENSILE, FIXED-KNOT FENCE MATERIALS

This next-generation fencing system features woven-wire steel mesh with a “fixed knot” designed for strength, safety, and breach resistance.

Key Features:

- Vertical and horizontal wires form a tight, interlocked grid.

- Stronger, longer-lasting, and more resistant to environmental wear compared to traditional field fencing.

- Customizable patterns to suit specific needs.

PERFORMANCE OF HIGH-TENSILE, FIXED-KNOT FENCES

When selecting high-tensile, fixed-knot wire mesh for high game fences, the five factors that make a performance difference are:

- Fixed-Knot Design

- Superior vertical strength for enhanced post spacing.

- Resists movement and impact, maintaining its shape and functionality over time.

- High-Tensile Wire

- Professional-grade 12.5-gauge wire is 175% stronger than traditional low-carbon alternatives, with a breaking strength of 1,380 lbs.

- Coating Type

- ASTM Class 3 galvanized coating offers three times the galvanization of typical Class 1 products and can last up to three times longer.

- Optional Zinc-Aluminum Class 40 coating for extreme environments provides the highest level of corrosion resistance.

- V-Crimps

- Deep crimps in horizontal wires act as springs, absorbing impact and maintaining tension over time.

- Mesh Spacing

- Available in various spacing configurations to balance security with functionality, ensuring optimal resistance to intrusion.

|

Interested in downloading and taking this article with you? Click to download the printable PDF version. |

BENEFITS OF HIGH-TENSILE, FIXED-KNOT SOLAR FENCING

- Best Value: Long-lasting Class 3 galvanized wire ensures durability and cost efficiency.

- Extended Lifespan: Manufacturer’s 20-50 year warranty and more than triple the lifespan of traditional fencing.

- Low Maintenance: Resists sagging and damage, requiring minimal upkeep.

- High Strength-to-Cost Ratio: Excellent balance of performance and affordability.

- Flexible Post Spacing: Posts up to 20 feet apart maintain strength while reducing installed costs.

- Resilience: Deep crimps and high-tensile materials absorb the impact of wildlife and climate change.

COST OF SOLAR FARM FENCING

Selection of the best fence for solar array farms often comes down to a value equation. High-tensile, fixed-knot Class 3 fences provide significant value, as detailed above. Over the long term, these superior fencing materials cost significantly less to install and maintain than Class 1 barbed wire fences or hinged joint field fences. The initial cost to install fixed-knot fencing is the same as barbed wire because of the 20-foot post spacing, which requires fewer intermediate posts. Also, this solar farm fence material comes in rolls of 330 feet or more, making it easier to install long runs versus installing wires individually. After installation, the fixed-knot fence requires little maintenance, translating into significant time and money savings. With a service life of 2-3 times that of a typical field fence, the high-tensile, fixed-knot fence is a no-brainer!

Key Considerations:

- Much lower installed cost compared to Chain Link

- Low maintenance results in the lowest cost of ownership

SPECIFICATIONS FOR SOLAR FARM FENCES

Fixed-knot wire comes in a wide variety of heights and wire spacings. Height is an essential aspect of selecting the proper fence material. To protect solar array farms, a 6-foot, high-tensile fence—1775-6 with barbed arms on top and three strands of barbed wire—is sufficient. This will keep humans, hogs, and other animals out. The high-tensile is suitable for hogs, and the barbed wire atop is for two-legged critters.

Spacing is an essential part of choosing the right fence, too. The space between wires should be small enough to prevent unwanted animals from breaching the fence. It needs to be large enough that smaller animals, such as mice, rabbits, and squirrels, can get out. Of course, the 1775-6 is 6 feet tall and set on 6-inch-wide fence mesh pattern spacings (or sections) within the fence. At the bottom, these are 3 inches tall and gradually increase to 4, 5, 6, and then 7 inches at the top of the fence.

The main choice to consider is the spacing between the wires, both vertically and horizontally. For best results, high-tensile, fixed-knot fence mesh, of course, the 1775-6 is 6 feet tall and set on 6-inch-wide fence mesh pattern spacings (or sections) within the fence. At the bottom, these are 3 inches tall and gradually increase to 4, 5, 6, and then 7 inches at the top of the fence.

GATES & WATER GAPS

Properly designing and installing gates and water gaps is critical to the performance of any fence system. Many factors must be considered to ensure the proper installation of gates and water gaps, as these are the two most essential links in the chain of security provided by the fence system. They are also the most technical and require planning, design, and execution to provide maximum functionality, performance, value, and ease of use by the property owner.

Considerations for gates are soil type, anchoring system, and stabilization to ensure long-term performance, swing direction, ground elevations, latch system, automation options, ground clearance, maximum open space to match containment or protection criteria, materials, durability, aesthetics, and budget for a net value equation that works for the project goals.

Water gaps are designed for locations where flowing water crosses a fence line. The purpose of the water cap is to maintain the fence’s security while allowing water and debris to pass through without building up and causing failure. A well-designed water gap will perform in severe weather events over time, ensuring reliable performance.

The functionality of these components of a solar farm fence is vital to the fence’s long-term performance, which keeps operating costs low over time and reduces the net cost of the investment. It’s the “Done Right the First Time” philosophy that typically costs a little more upfront to save countless dollars and headaches in the future and takes the concerns of fencing out of the equation for more time spent on enjoying your exotic game.

The professionals at Tejas Ranch & Game Fence use proven methods acquired through years of experience in the business to ensure a good fit and a long-lasting solution with the pride and workmanship that guarantees top performance in the ranch fence world.

SUPPORT POSTS AND CORNERS

Having been around farms and ranches, you have seen all types of fence support systems, also known as bracing, from railroad ties and cedar posts to trees and rock piles. A good rule of thumb to remember when choosing materials and quality installation for your next solar farm fence is that the structural support system has set the foundation for a reliable herd management tool for many decades.

Fence Brace Material

The most reliable fence bracing materials for farms and ranches are made from galvanized pipe. This post material is used to build an H-brace’s corners, pull posts, and line posts, which are the actual structures of the fence system that hold the tension of the high-tensile, fixed-knot wire mesh fence to maintain its integrity to perform as a reliable barrier. This material is an ideal match of strength, long service life due to its corrosion protective layer, and relatively low cost considering the near maintenance-free 25+ year service life.

Structural Brace Construction

The fundamental bracing method of having a structural anchor at each terminal and turn point on a fence has been around for decades, but quality ranch fence contractors have perfected it. On a typical H-brace or corner brace, a 3” galvanized post is driven a minimum of 5.5 to 7 feet into the ground, depending on the soil type and density. It is essential to drive the tension-bearing post down to gain ultimate resistance from the soil. Soil types and compaction rates vary, and corresponding construction methods must, too. Using rule-of-thumb engineering and years of experience, the professionals at Tejas are adept at setting these critical anchor points to perform for the life of the fence, guaranteed.

Once the posts are set, horizontal cross members made of galvanized pipe are welded between the vertical posts. For maximum strength, a diagonal kicker brace is attached to the structure and then to a deadman. The pipe welding should be a complete 360 degrees and, when done right, fully penetrate the base metals to create the rigidity to support the 2-3,000-pound tension of the high-tensile, fixed-knot fence without moving for the life of the fence.

This construction practice provides a heavy-duty anchoring point for all the tension that will be applied to your solar farm fence over the years.

Fence Fabric Support Posts

With a fixed-knot wire mesh fence, we recommend T-post spacing on 20-foot centers. This distance can be slightly more or less depending on several variables, including topography, animal traffic, and soil types. A fixed-knot fence’s rigidity and vertical stays allow it to perform exceptionally well with nominal 20-foot post spacings. The savings of 20-foot intervals offset the high-tensile wire’s increased cost and result in a much stronger and longer-lasting product. T-posts and Line Posts can be spaced on tighter intervals in high-pressure areas or with exotics that put more pressure on a fence.

Additional fence wire support is added through line posts, which are single pieces of pipe driven into the ground along the fence line at 100’ to 120’ intervals and take the place of T-posts at those locations. The primary purpose of these line posts is to give the fence fabric good lateral stability on long runs between the primary bracing structure.

ADDITIONAL OPTIONS

Depending on the project goals, other features may be required and can be added to customize fence solutions for almost any environment or need.

Visual Impact

Site block screening and buffering can significantly minimize the visual impact of utility-scale solar facilities. When establishing a solar farm operation, rural aesthetics are often a top concern of neighbors and municipalities. Buffering or screening may be necessary along main roads, public right-of-ways, highways, or other areas.

Three Options for Reducing Visual Impact

- Screening – Commonly referred to as wind screen, a commercial-grade screening material can be applied to the high fence with little visibility. At Tejas, we refer to this as “site block.”

- Black Powder Coating – To create a fence that blends in with the environment and does not reflect light like traditional galvanized pipes, a black powder coating can be added to the fence materials during production to create a desired finish with long-lasting durability.

- Buffering – Berms can provide an effective visual screen, particularly if combined with landscaping and vegetation.

Predator-Control Barriers

Predator-control options consist of a steel mesh apron fence at the base of the fixed-knot fence to eliminate digging, tunneling, and wallowing; or electric wire barriers at the base and/or center and top of the fence.

Barbed wire can be placed at the top of the fence to deter climbing and jumping.

Electric Fences

An electric fence wire outside of the fence at approximately 6 inches above the ground has considerably reduced the number of breaches under a fence. An electric wire is typically used to prevent coyotes or dogs from digging a hole under the fence.

Zinc-Aluminum Coating

For highly corrosive environments, such as coastal areas where salt-laden air rusts fences more quickly, we offer a zinc-aluminum coating that is highly corrosion-resistant. This Class 40 zinc-aluminum coating provides the highest degree of protection available for high-tensile steel mesh.

WHY CHOOSE TEJAS?

Choosing the right solar farm fence contractor to build the best fence for solar farms.

The highly skilled team of fencing innovators, designers, and construction professionals at Tejas are dedicated to excellence in every job. They work closely with clients to determine the best design and construction for their unique needs, using only the highest quality fencing materials. Their installation teams are meticulous and accomplished experts in every way. Tejas strives to exceed clients’ high expectations to create sustainable value in all solutions by focusing on careful consultation and design, top-quality materials, and uncompromising installation methods. Choose Tejas for the best fence for a solar farm on your property.

|

Interested in downloading and taking this article with you? Click to download the printable PDF version. |