It’s time to phase out wood posts, single-strand, barbed-wire, and field fencing enclosures with the latest fixed knot fence.

Fences. They’re a sign of the of the American frontier. They’re meant to hold things in, keep things out, and establish obvious boundaries. Many different types of fencing have been devised throughout the past couple centuries, but the game is changing.

The Evolution of Ranch Fencing

In the beginning, ranchers’ livestock freely roamed the open range. Then, in an effort to contain cattle and prevent crop destruction, ranchers built wooden fences. Supplies were expensive and limited. So, the next phase of fencing was the single-strand wire fence, but it was easily broken by cattle.

Necessity is the mother of invention, and thus, the barbed-wire fence was born. Developed over 150 years ago, the first patent in the United States was issued for barbed-wire in 1867. Today, it remains a popular choice for livestock owners, but it too eventually gave way to something better.

Over the past few decades, barbed wire was joined by field fencing which is made of low tensile steel and fashioned into a hinged-joint mesh. Mesh fence improved versatility and predator control. While barbed wire is meant to hold large livestock, field fence can hold a variety of animals, big and small. Horses, sheep, goats and other animals are better contained with field fencing, making it a more versatile choice for ranchers who raise other livestock in addition to cattle. Plus, with more wire per sq. foot, the field fence offers smaller openings, which are more difficult for unwanted predators to breach.

However, field fencing has flaws, with the biggest being increased maintenance. It can lose shape rather quickly and can be subject to sagging and breakage. This requires installation of more stay posts, which increases costs. Ultimately, while better than barbed wire in some respects, field fences still require long-term fixes.

However, field fencing has flaws, with the biggest being increased maintenance. It can lose shape rather quickly and can be subject to sagging and breakage. This requires installation of more stay posts, which increases costs. Ultimately, while better than barbed wire in some respects, field fences still require long-term fixes.

As with most things, improvements in technology continue, and ranch fencing is no exception. At Tejas, we acknowledge and respect the roles that classic, historical fence options have played in ranch development, but we don’t resist innovation.

Due to drawbacks of historical options, and improvements in technology, the next generation of ranch fencing was developed to mitigate long-term maintenance. The high-tensile, fixed-knot fence is that solution. It’s the future of fencing.

Due to drawbacks of historical options, and improvements in technology, the next generation of ranch fencing was developed to mitigate long-term maintenance. The high-tensile, fixed-knot fence is that solution. It’s the future of fencing.

While taking a form somewhat resemblant of the old field fence, it features a series of interconnected vertical and horizontal wires that form squares and rectangles of overlapping and wound wires. High-tensile, fixed-knot fencing outperforms traditional barbed wire and hinged-joint field fences in virtually every application. It offers superior versatility, durability, and safety. It is an all-encompassing fence solution. It can house all varieties of livestock — both big and small — and promotes keeping predators out.

Fencing Choices and Considerations

When selecting a ranch fence, basic wire choices need to be made, including knot type, tensile strength, gauge, galvanization, and mesh spacing. In most applications, the best value is the fixed-knot, high-tensile, 12-gauge, Class-3 galvanized, with 6 inches or less of mesh spacing. These combined qualities create a fence that is superior in value based on cost and performance.

Still, what exactly does all of this mean? Read on to familiarize yourself with the different factors that make up this best-value winner.

Knot Type

The most familiar knot that we all recognize is the barbed-wire knot. It consists of two wire strands twisted together and starred with either 2- or 4-point barbs at intermittent distances.

The second type is the hinged-joint knot. This is formed by wrapping the vertical stay wire pieces around the line wire at each intersection.

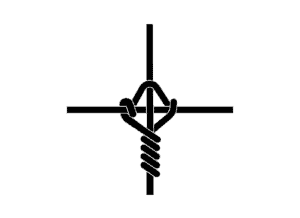

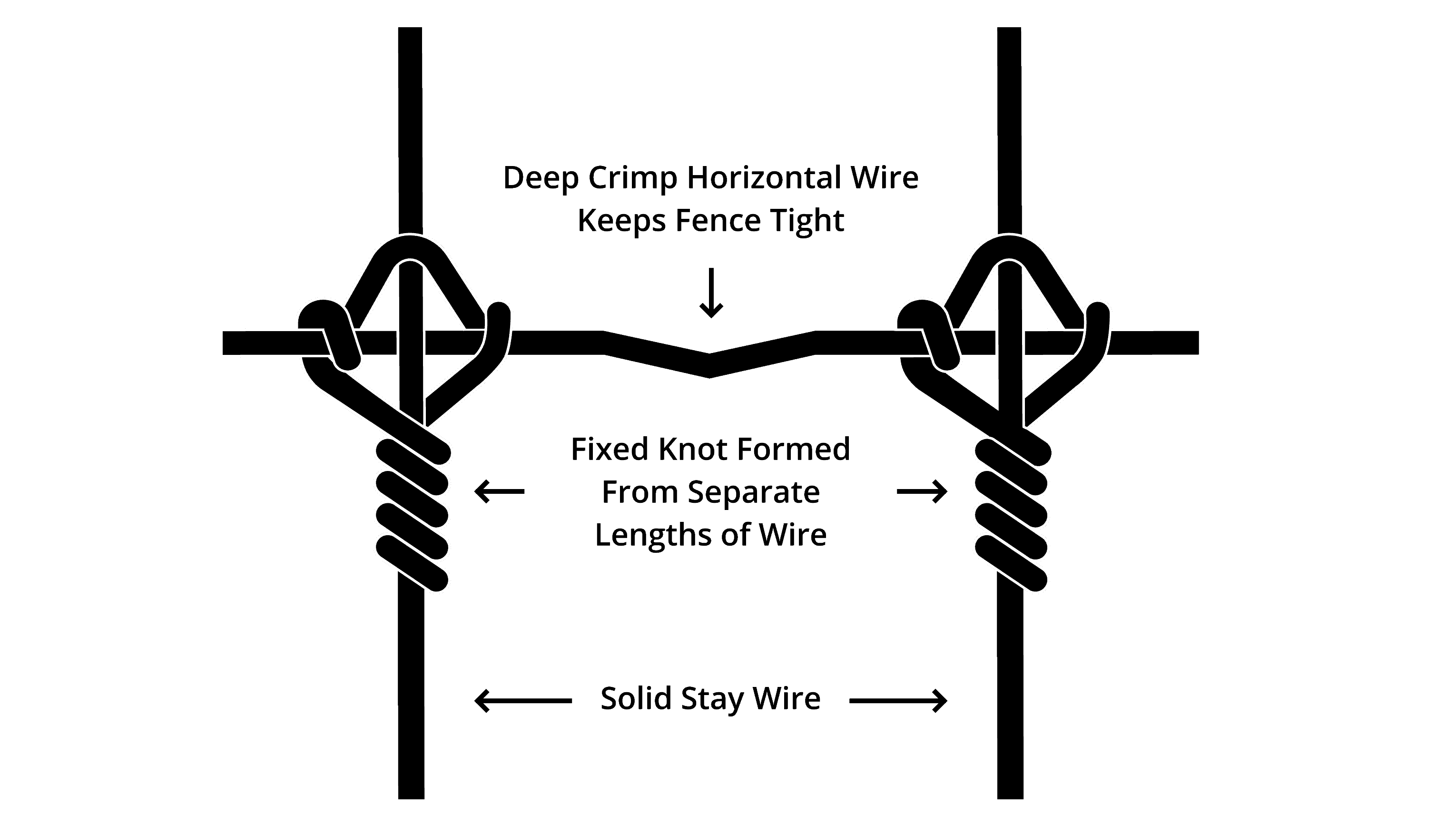

Lastly, the fixed knot utilizes a separate piece of wire that’s tightly wound and knotted around the line wire and stay wire.

Lastly, the fixed knot utilizes a separate piece of wire that’s tightly wound and knotted around the line wire and stay wire.

Of these options, Tejas’ choice is the fixed knot fence. It is considered the premium option, and tests have proven it has the highest vertical strength, moving and loosening less under pressure.

Tensile Strength

Wire strength is expressed as tensile strength. The tensile strength of a material is the maximum amount of tensile stress that it can take before failure, for example breaking. As such, wire strength is largely dependent on its carbon content, and wire fencing products are manufactured using either low-carbon or high-tensile wire.

Low-carbon wire is made from a steel rod with a carbon content of approximately 0.10%. This type of wire is easy to work with and fairly forgiving, allowing for increased stretching and elongation. High-tensile wire is made with higher carbon content at approximately 0.28%. By almost tripling the carbon content the wire strength significantly increases and reduces stretching and elongation.

Between the two options, Tejas’ chooses high tensile. Our product framework is among the highest-strength steel available for fencing. With a tensile strength of 50,000 psi, it is more than 45% stronger than standard steel, leading to reductions in elongation, and minimizing the need for future tensioning and repair work.

Furthermore, high tensile combined with the fixed knot produces the strongest woven-wire fence available on the market. Pairing these together make it highly resistant to livestock and wildlife damage, such as wild hogs. Superior construction prevents wild hogs from breaching the fence fabric like they do in low-tensile, field-fence wire. In fact, the breaking strength of each horizontal, 12-gauge wire is around 1,380 lbs. Additionally, crimps in the horizontal high-tensile wires are installed with significant tension, so they resist force in spring-like fashion, which helps retain shape and strength. With proper installation, good maintenance consists of routine checks for damage from falling trees, and that’s it.

Gauge

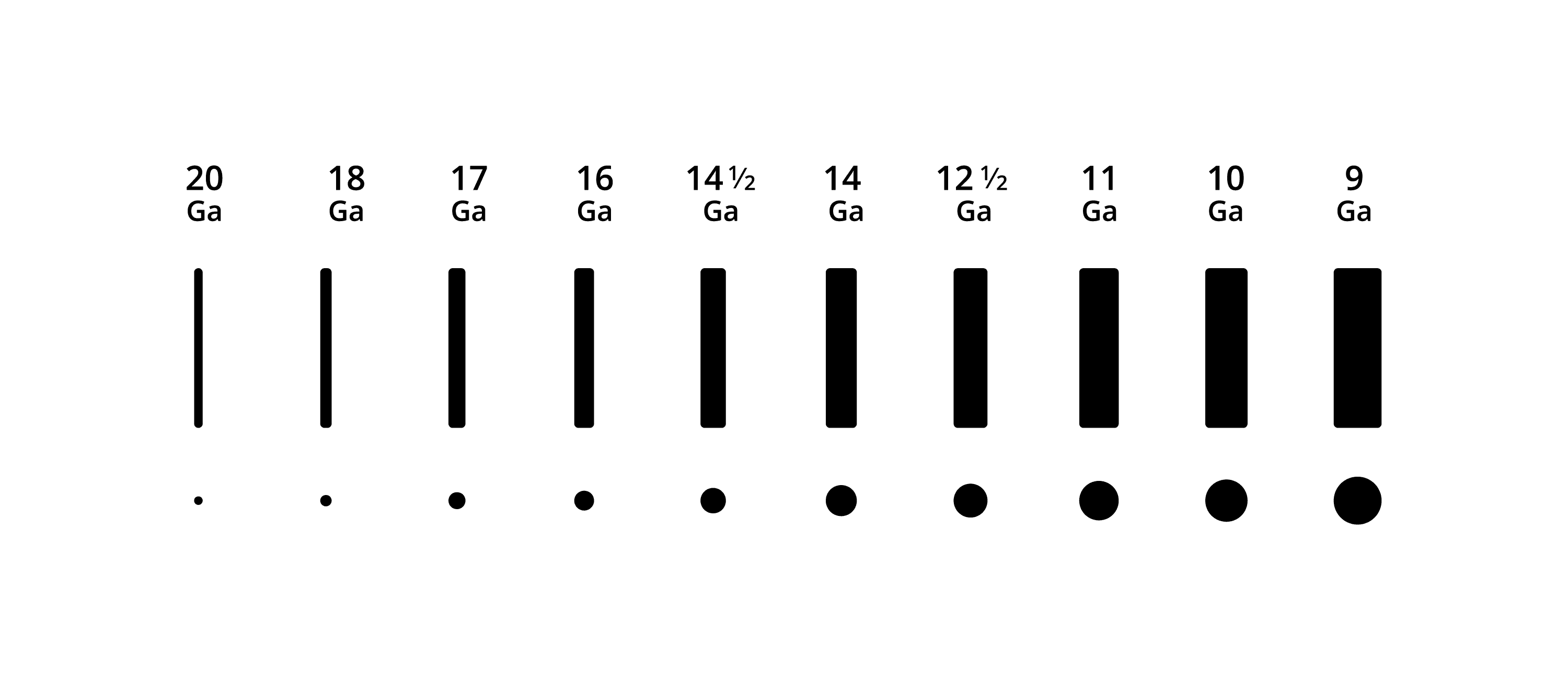

Size of wire is expressed as gauge, which signifies its thickness or diameter. As the gauge number increases, the wire size decreases. Basically, the bigger the number, the smaller the wire. A lower-gauged (thicker) wire is best used for heavy animals that press against the wire. A higher-gauged (thinner) wire is sufficient for small, lightweight animals.

In most cases, Tejas chooses the 12.5-gauge diameter as the top choice in typical ranch fence applications. Although recommended gauge varies depending on specific needs, 12.5-gauge works for most installations and will keep livestock safe and secure. Professional-grade 12.5-gauge, high-tensile wire is 175% stronger than traditional low-carbon options.

Galvanized Coating

The galvanization process includes dipping the manufactured product in hot molten zinc, or in some cases, zinc and aluminum. Thickness of the galvanized coating is ranked by class, indicating its life expectancy.

Class 1 is the industry standard and has 0.28 ounces of zinc coating per sq. foot. Class 3 is applied at 0.80 ounces per sq. foot. This coating weight is three times greater than Class 1. Class 40 (zinc-aluminum) coating provides the highest degree of protection available on the market. It is designed for fence installations in highly corrosive areas. The zinc-aluminum hybrid base coat extends the life of the wire by up to two times that of Class 3 galvanized wire.

Tejas’ choice? In most cases, Class 3 galvanized. As reported, it can last three times longer than Class 1, effectively lengthening the lifespan and reducing overall cost of ownership. Plus, it requires very little maintenance, and landowners spend less time worrying about the durability and integrity of the fence. That said, for highly corrosive coastal areas where salty sea breezes can increase corrosion, Tejas recommends Class 40 zinc-aluminum coating.

Fixed Knot Fence Mesh Spacing

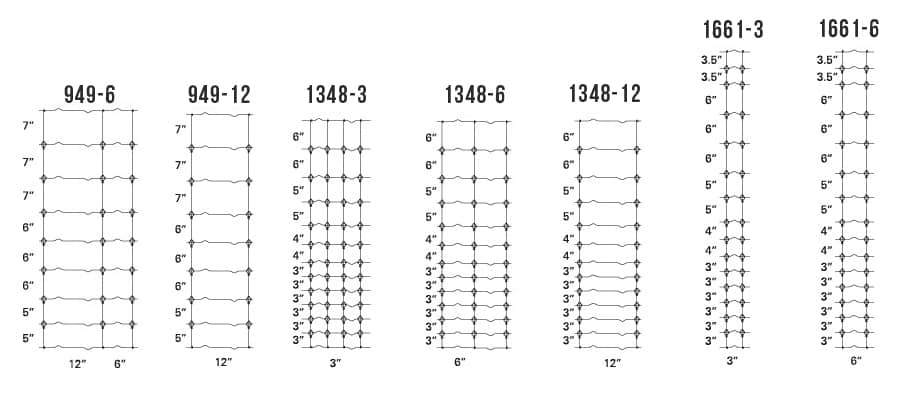

High-tensile, fixed-knot fences are available in a variety of heights and configurations. Mesh designs are available in 3- to 12-inch vertical stay wire spacing with 3-inch minimum and 5-inch maximum horizontal wires in the two bottom courses. Selection depends on specific goals for the enclosure.

Most manufacturers use a standard numbering system to designate their woven-wire designs. Generally, the first digit represents the number of horizontal wires. The second and third digit expresses the height of the fence (in inches). The fourth and fifth digit reveals the vertical stay wire spacing (in inches).

For example, Stay-Tuff product number 949-24 (pictured above) means the wire has 9 horizontal wires, is 49 inches tall, and has 24 inches of spacing between vertical wires. The 949-12 means it has 9 horizontal wires, is 49 inches tall, and incorporates 12 inches of spacing between the vertical wires. The 1661-3 has 16 horizontal wires, is 61 inches tall, and offers 3 inches of spacing between the vertical wires.

With a wide range of height and mesh pattern options, Tejas proudly shares that fixed-knot mesh fencing is versatile and easily customized to fit individual needs of the rancher. For containing livestock, a standard 4- to 4.5-foot height is sufficient. The best cattle fence stands 49 inches tall, has 9 horizontal wires, and sports 6-inch vertical spacing. For high-traffic areas such as corals, turnouts, or birthing pens, 3-inch vertical spacing provides greater strength and security. Tighter-spaced fencing also is more durable and resistant to pressure in high-traffic areas.

For hunting or breeding operations requiring a high fence, an 8-foot high fence is optimal. For best results, we recommend high-tensile, fixed-knot fence mesh. This is a sturdier, longer-lasting option that is less susceptible to damage.

For predator control, Tejas recommends varying wire mesh spacing with smaller mesh spacing along the bottom of the fence and using a form of predator wire as an addition to the standard fence.

To recap, for minimal maintenance, high-tensile, woven-wire steel mesh with a fixed-knot design is the foundation for the best ranch fence. This is the material of choice for holding livestock and wildlife. It is preferred over five-strand barbed wire and hinged-joint fencing for its strength, safety, and resistance to breach. High tensile, fixed knot, 12-gauge, and Class 3 galvanization are combined qualities that create a fence far superior in performance and cost.

Fixed-Knot Fence by the Numbers

The selection of a ranch fence often comes down to a value equation. High-tensile, fixed-knot Class 3 fences provide significant value. With the benefits of higher performance and excellent longevity, the material net cost per year to install this fence makes it the best value to own.

The initial cost to install fixed-knot fencing is virtually the same as barbed wire because of the 20-foot post spacing, which requires fewer intermediate posts and no fence stays or stiffeners. It comes in rolls of 330 or 660 feet, which facilitates installing long runs versus installing individual wires. Considering the long term, these superior fencing materials cost significantly less to maintain than Class 1 barbed-wire fences or hinged-joint field fences. With a service life of two to three times that of typical low-carbon barbed wire and hinged-joint fencing, high-tensile, fixed-knot fence translates to significant savings of time and money.

Fixed Knot Fence Value Comparison

| $ per L.F. | Braces & Gates | Net Cost Per Mile | Useful Service Life | Annual Cost Per Mile | |

|---|---|---|---|---|---|

| Barbed Wire, 5-strand | $3.33 | $3,000 | $19,082 | 15 | $1272 |

| Field Fence, Low Tensile | $3.37 | $3,000 | $19,267 | 10 | $1,927 |

| Fixed-Knot, High Tensile 949-6 | $3.33 | $3,000 | $19,188 | 30 | $640 |

Chart Conclusion: High-tensile, fixed-knot fence is nearly 100% less expensive to own over time than barbed wire and almost 200% less than field fencing.

Chart Notes: Service life is based on Class 3 galvanization, which is three times thicker than Class 1 galvanization applied to typical barbed wire. Greater galvanization provides a much longer service life in typical applications.

The 2-mile basis of comparison uses Tejas standards of spacing, galvanized pipe, and t-posts.

Why Choose Tejas?

It’s important to choose the right ranch fence contractor to build the best possible high-tensile, fixed-knot fence. Tejas’ highly-skilled team of fencing innovators, designers, and construction professionals are dedicated to excellence. They work closely with clients to determine the best design and construction for their unique needs and use only the highest-quality fencing materials. Their installation teams are accomplished, meticulous experts. By focusing on careful consultation and design, top-quality materials, and uncompromising installation, Tejas strives to exceed clients’ high expectations to create sustainable value. Choose Tejas for the best fence solution for your property.

Request a Fixed Knot Fence Estimate